Integrated control of Philips Dynamic GreenPower LED modules

May 2017 - Nijssen introduces its own control of the Philips Dynamic GreenPower LED production modules. The control protocol and the PLCs are integrated into the Nijssen Control Systems. The lighting is controlled from the visualization of the operating system.

The Philips Dynamic GreenPower LED growth modules are made up of different LED colors within the light spectrum (far red, red, white and blue). For each color, the light intensity can be adjusted to fully customize the light spectrum as preferred.

Highly versatile lighting solution

Edwin Snabel, business unit manager Climate Technologies at Nijssen: "New to these modules is that all colors are housed in one lamp. This creates even more lighting uniformity to each plant. Because any desired spectrum can be compiled, researchers and growers can apply a variety of light recipes in a simple and flexible manner to a wide variety of crops. Research on light recipes is booming business, as growers can develop specific plant properties in this way. In particular, Nijssen developed the mobile climate room MyGrowthRoom, which can also be rented for testing purposes."

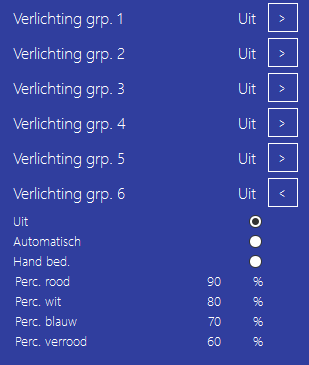

Multiple lighting groups individually adjustable

The LED modules are controlled via the DMX protocol for lighting equipment. This makes it possible to create multiple lighting groups in a room, which can be individually controlled. The definition of these lighting groups is software-based. Because no additional IO and cabling is required, this is also a cost-effective solution.

All conditions precisely controlled

In addition to lighting, a plant growth recipe includes settings e.g. for temperature, humidity and ventilation. With the Nijssen Control System all relevant parameters are set and monitored via the same visualization. Logged set-points can be easily saved as a growth recipe. This guarantees repeatability under 100% equal conditions.

Pioneer in Vertical Farming

It’s not the first time that Nijssen integrated light management in their control systems. Already in the mid eighties, Nijssen realised the potential of coloured LED lights for plant growth. At its Research Centers in Leiden and Wageningen, Nijssen Light Division B.V. implemented fluorescent lights and a LED light interface for light control, as early as 1986, as part of its fundamental research on light in climate rooms. Back in the days, under a much lower light output of older generation LED lights, promising results were presented, such as stenting, stimulation of rooting, stretching of plants or producing more lateral shoots, accelerating early blooming.

Focus on core-business

The first growth lamps were expensive and had a low light output. A commercial application in large-scale projects would ask for years of development. Therefore Nijssen decided to concentrate in the nineties on their core business. The Light Division was (reluctantly)sold to a renowned international lighting manufacturer.With the acquired expertise, Nijssen continue to apply in realizing innovative climate rooms. This is how we became a popular knowledge partner for a large number of universities, research institutes, seed producers and propagators worldwide.

Phytotrons for BVB Substrates

Among others, BVB Substrates in De Lier will make use of the new control module. Nijssen realizes two phytotrons and a semi-closed greenhouse in their newly built research site. The R & D department of BVB Substrates is doing weed tests and growth tests. The high-tech phytotrons are used to develop substrates for multi-layer production. By assessing problematic situations in practice, well-founded cultivation advice can be given.